Trends and Advances in Packaging Machines for the Chemical Industry

In the chemical industry, efficiency and safety in product packaging is key to ensure quality and regulatory compliance. Industrial packaging machines have evolved significantly, integrating advanced technologies to optimize processes and minimize waste. From automatic fillers to ATEX packaging systems, innovation is transforming the way chemical products are prepared for distribution.

The Importance of Packaging in the Chemical Industry

Chemical packaging not only influences commercial presentation, but also plays a fundamental role in the safety, preservation and regulation of potentially hazardous substances. Inadequate packaging can lead to leakage, contamination and storage problems. Therefore, specialized packaging machines ensure that each substance is stored correctly, reducing risks for both operators and the environment.

Key Technologies in the Packaging of Chemical Products

1. ATEX Packaging Systems

ATEX regulations regulate the handling of flammable and explosive substances in the chemical industry. ATEX certified packaging machines are designed to operate in hazardous environments, avoiding sparks and accumulation of electrostatic charges that can generate fires or explosions.

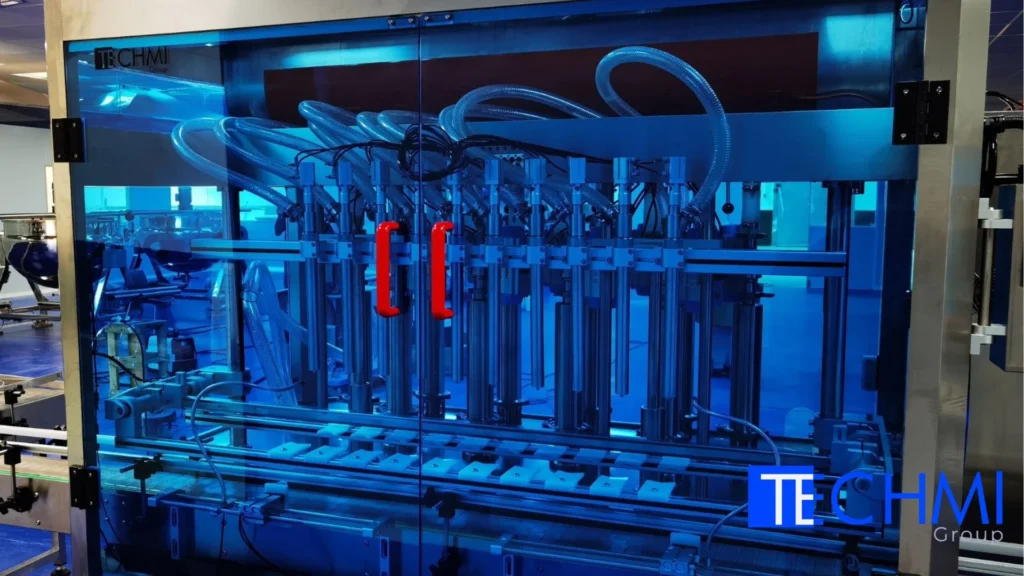

2. High Precision Filling

Accurate dosing is vital in the chemical industry, where every milliliter counts. Technologies such as volumetric and gravimetric fillers enable precise packaging, reducing material waste and improving the consistency of the final product.

3. Automation and Intelligent Control

Packaging machines have incorporated advanced sensors and artificial intelligence to monitor and adjust the process in real time. This not only improves efficiency, but also enables early detection of faults, minimizing downtime.

Did you know that…?

The first automatic packaging machines were developed in the early 20th century, but today, with the advent of Industry 4.0, modern systems can self-correct errors, detect packaging faults and optimize input consumption in seconds.

Benefits of Implementing Modern Packaging Machines

- Increased efficiency and speed in product packaging.

- Waste reduction thanks to precise dosing systems.

- Compliance with international safety regulations.

- Reduction of contamination risks.

- Optimization of operating costs through automated processes.

The evolution of industrial packaging machines has revolutionized the way the chemical industry handles its products. Implementing advanced technologies not only improves safety and efficiency, but also boosts sustainability and competitiveness in the marketplace.

If your company is looking to optimize its packaging process with the best technological solutions, contact us and find out how we can help you innovate your production line.