Have you heard of Solid State Fermentation (SSF)?

Although its name sounds very technical, it is an ancient technique that has re-emerged as an innovative and sustainable solution to the challenges of our global food system.

What is SSF?

In essence, SSF is a fermentation process where microorganisms grow on a solid substrate in the absence or near absence of free water. Imagine mold growth on compost or leaf litter; SSF seeks to mimic these natural environments to take full advantage of microbial metabolism. The fascinating thing is that the solid substrate itself not only serves as a support, but also provides all the necessary nutrients, often without the need for chemical additives.

Advantages:

SSF offers multiple benefits that position it as an attractive and more sustainable alternative to traditional liquid (submerged) fermentation. Here are some of its key advantages:

- Lower Water and Energy Consumption: Uses a minimum of water, which reduces energy consumption for sterilization, cooling and wastewater treatment.

- Valorization of Agro-industrial Waste: Allows the transformation of agro-food industry by-products, such as fruit peels, bran, bagasse and coffee residues, into high-value products, contributing to the circular economy and reducing environmental pollution.

- Increased Productivity and Product Stability: By placing the microorganism in close proximity to the substrate, higher product concentrations and yields are achieved, with improved stability due to the protective environment of the solid substrate.

- Simpler and More Cost Effective Processes: SSF systems are typically less expensive to design and maintain, with lower infrastructure requirements and often easier and less costly downstream processing for product extraction and purification.

High Value Products and Applications:

SSF has proven its versatility in the production of a wide range of essential products for various industries:

1. Biofertilizers: Allows to increase the fermentative performance of some fungi with biostimulant action such as Trichoderma harzianum and Metarhizium anisopliae. The fermentation in solid state promotes a thickening of the cell wall, increasing both the perisporic and endosporic layers. This change is associated with a higher content of β-glucans, chitin and wall proteins, which reinforces the resistance and stability of the mycelium or spores against the most demanding conditions of the process, optimizing their adaptability to different environmental conditions and agricultural substrates. In addition, this technique improves the viability and production of bioactive metabolites of these biological agents.

2. Industrial Enzymes: This is the preferred method for the production of enzymes such as amylases, xylanases, lipases, cellulases, pectinases, fructosyl transferases and lactases. This is because the almost total absence of water keeps the enzymes produced more stable. These enzymes have massive applications in food and feed, bioenergy, pharmaceuticals and waste treatment.

3. Functional Foods and Protein Enrichment: Allows to significantly improve the nutritional value of foods. An example of this is the fermentation of beans with Pleurotus ostreatus. This SSF increases protein content, enriches essential amino acids (such as valine, leucine, isoleucine and tyrosine) and reduces anti-nutritional factors, such as phytic acid, to almost undetectable levels.

4. Plant-Based Meat Analogues (PBMA): SSF is an effective method to create PBMA. By fermenting soy proteins with microorganisms such as Rhodotorula mucilaginosa, Monascus purpureus and Lactiplantibacillus plantarum, the color, texture and flavor of meat can be simulated, while reducing anti-nutrients and promoting the cross-linking properties of proteins.

5. Antibiotics: Allows the production of antibiotics with low investment and high productivity, such as oxytetracycline and cefamycin C.

6. Organic Acids and Biofuels: Enables the production of organic acids such as citric acid and lactic acid, as well as biofuels such as bioethanol, biodiesel and biogas, using agro-industrial waste.

The Role of Bioengineering and the Future:

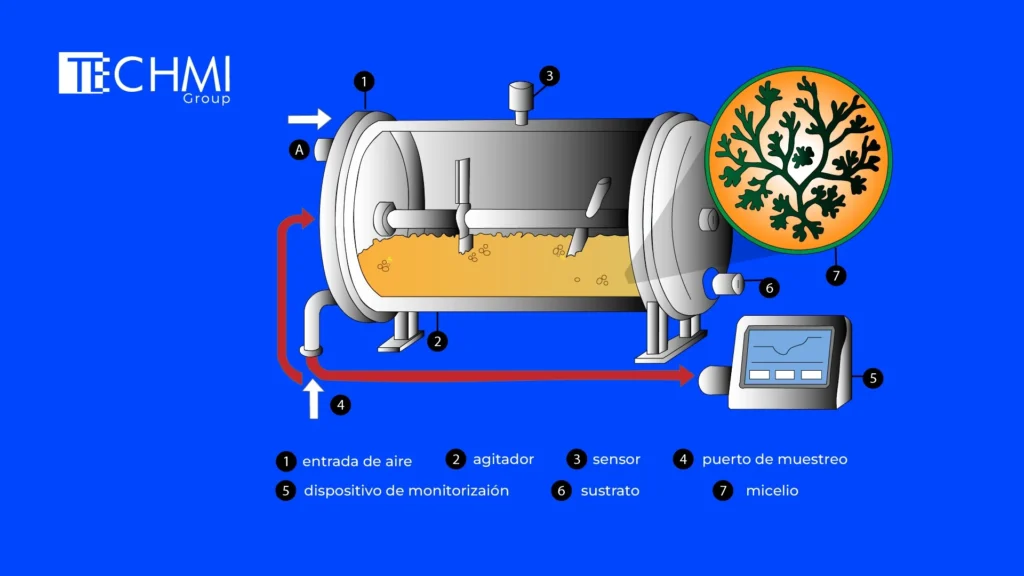

Although SSF has faced historical challenges such as scalability and product recovery, advances in bioengineering are opening new doors. Innovative bioreactor design, genetic and metabolic engineering of microorganisms, and the use of advanced modeling techniques are making it possible to optimize microbial growth and metabolite production, overcoming problems such as heat and mass transfer.

It is expected that with continued automation and the integration of omics techniques and artificial intelligence, Solid State Fermentation will reach the efficiency and large-scale impact of other fermentations.

At TECHMI Group we have designed a horizontal type Solid Fermenter, the TECHMI FES.

Find out more at techmigroup.com

📩 Write to us if you want more information about solid fermenters clientes@techmigroup.com