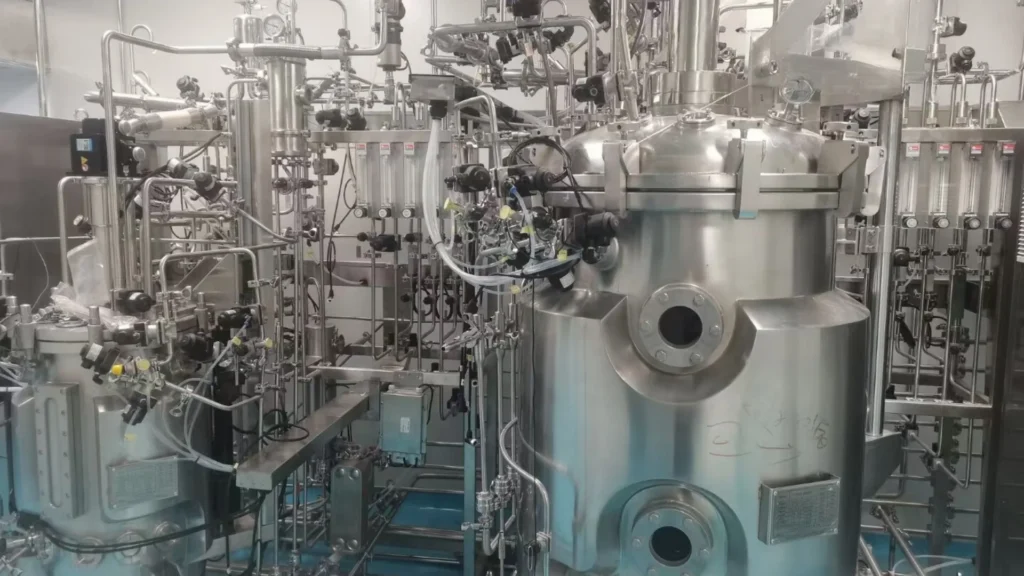

30,000L INDUSTRIAL BIOREACTOR FERMENTER

Industrial bioreactor and fermenter up to 30,000L

What is a 30,000L industrial fermenter / bioreactor?

30,000L INDUSTRIAL BIOREACTOR FERMENTER

TECHMI BIO INDUSTRIAL is a fermentation control system with stainless steel fermenter designed according to your needs and requirements, oriented to biotechnological production. It is equipment for fermentation productions up to 30,000 liters.

They are essential to ensure sustainable and scalable production. Thanks to their innovative design, they maximize the efficiency of bioprocesses.

Pharmaceutical industry

Production of antibiotics such as penicillin, streptomycin or erythromycin.

Manufacture of vaccines using cell culture or microorganisms.

Obtaining recombinant proteins such as insulin or growth hormones.

Production of enzymes used in medicines and diagnostics.

Food and beverage industry

Fermentation for the production of products such as yogurt, cheese, vinegar, bread and beer.

Production of probiotics and food supplements.

Production of amino acids, such as monosodium glutamate or lysine, used as food additives.

3. Biotechnology and bioenergy

Production of biofuels such as bioethanol or biogas from agricultural or industrial waste.

Development of bioplastics from microorganisms such as PHA (polyhydroxyalkanoates).

Production of biofertilizers using nitrogen-fixing or plant growth-promoting bacteria.

4. Cosmetic industry

Cultivation of microorganisms to produce hyaluronic acid, collagen and other active ingredients used in beauty products.

5. Research and development (R&D)

Studies of microbial behavior under different conditions to develop new products.

Optimization of industrial processes by scaling up from laboratory to pilot plant.

Development of new genetically modified microorganisms for specific applications.

6. Chemical Industry

Production of chemical compounds such as organic acids (lactic, citric or acetic acid).

Obtaining biodegradable polymers.

7. Agriculture and livestock

Production of enriched silage for animal feed.

Cultivation of microorganisms to protect crops against pests or diseases.

8. Waste treatment

Fermentation for the degradation of organic wastes and their conversion into useful products, such as compost or energy.

Products

Related Products

In this category, you will find more products.