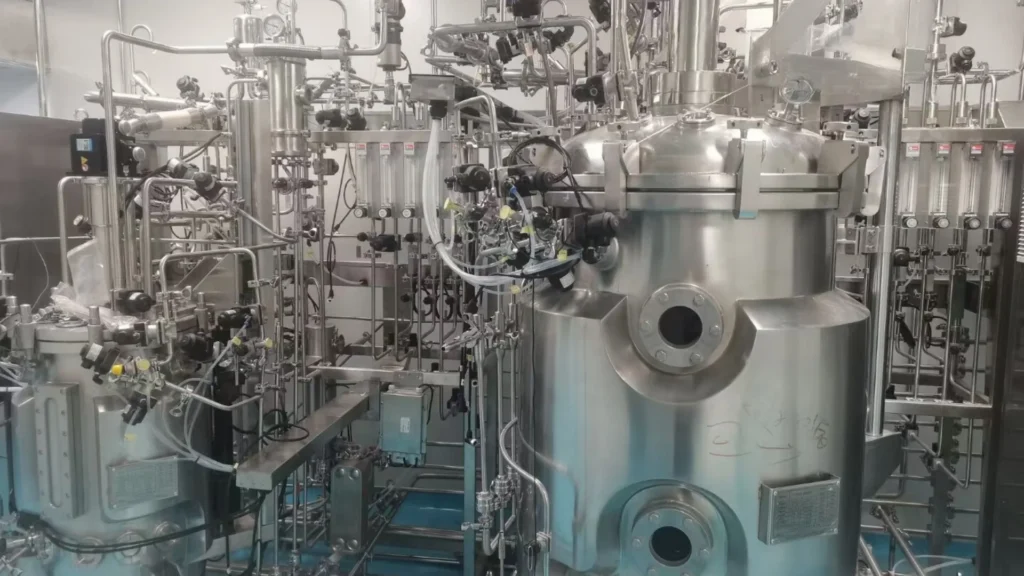

FERMENTER TECHMI BIO 500 FERMENTER BIORREATOR FERMENTER

500-Liter-Industriefermenter und Bioreaktoren

Wie funktioniert unser Techmi Bio 500 Fermenter?

FERMENTER TECHMI BIO 500 FERMENTER BIORREATOR FERMENTER

TECHMI BIO 500 ist ein Fermentationskontrollsystem mit einem 500-Liter-Fermenter aus Edelstahl, das für die biotechnologische Produktion konzipiert wurde.

Ein Bioreaktor ist eine Vorrichtung zur Aufrechterhaltung einer kontrollierten und optimalen Umgebung, die das Wachstum und die Entwicklung von Mikroorganismen, pflanzlichen oder tierischen Zellen erleichtert. Sie ermöglichen die effiziente und reproduzierbare Durchführung von biologischen Prozessen, wie z. B. Fermentationen. Es handelt sich um ein unverzichtbares Gerät in einem biotechnologischen Labor, das sich ideal für Forschung und Entwicklung oder für die Einleitung eines Fermentationsprozesses eignet.

Es ist ein ideales Gerät für kleine Produktionen oder das Scale-up größerer Produktionen, das als Zwischenschritt von Scale-up-Fermentationsketten verwendet wird.

Der 500-Liter-Fermenter der TECHMI-Gruppe aus 316L-Edelstahl ist ideal für kleine Produktionsläufe oder als Zwischenschritt in Scale-up-Zügen zu industriellen Mengen. Er bietet eine präzise Steuerung kritischer Parameter wie Temperatur, pH-Wert, Sauerstoff und Rühren und gewährleistet so optimale Bedingungen für Bioprozesse in der Biotechnologie, Pharmazie, Lebensmittelindustrie und Bioenergie. Sein robustes, leicht zu reinigendes Design entspricht internationalen Standards und gewährleistet Konsistenz und Qualität in der Produktion und erleichtert die zuverlässige Skalierbarkeit von Pilotanlagen bis hin zur großtechnischen Produktion.

Produkte

Verwandte Produkte

In dieser Kategorie finden Sie weitere Produkte